We understand the temptation to “wait just one more year” before investing in Cedar maintenance. Whether it’s budget-related or just a busy schedule, many homeowners try to push the limits of their cladding.

We regularly see the results of both proactive care and long-term neglect. While Cedar is incredibly resilient, there is a definitive tipping point where a simple maintenance coat turns into an expensive restoration – or worse, a total reclad.

Here is a breakdown of the Cedar timeline and how to know if you’ve gone too far.

The Three-Summer Rule

We recommend having the sun-exposed faces of your Cedar recoated every 2-3 summers.

The “danger zone” usually begins after the third summer. However, not all sides of your house age at the same rate.

North-Facing (the sunny side):

After three summers of UV exposure, maintenance is officially overdue. You’ll notice the oil’s tint beginning to discolour and areas of bare timber becoming exposed.

Without oil, the Cedar loses its ability to repel water. It absorbs moisture during rain and then gets baked dry by the sun. This rapid swelling and shrinking is what starts the deterioration process.

South-Facing (the sheltered side):

You can often get away with three summers or longer here, but you aren’t out of the woods. While UV isn’t the enemy, dampness is.

High-quality Cedar oils contain fungicides that prevent organic growth. As the oil dries out, these fungicides disappear and you’ll see mould and lichen developing.

The Downward Spiral: 4 to 6 Years

If you push past the four-year mark without treatment, the life begins to leave the boards.

Around the 4-year mark, you will likely see mould developing on sheltered, damp faces. On the sunny side, the boards will begin to warp or crack as they lose their internal moisture.

At 5–6 years, maintenance now becomes urgent. At this stage, the weaker parts of the Cedar boards (the thinner overlap points) will start to bend and cup. Gaps will appear between boards, which can lead to serious waterproofing issues for your home’s structure.

Can Your Cedar Be Saved?

The good news is that in most cases, Cedar can be saved – but it comes at a cost.

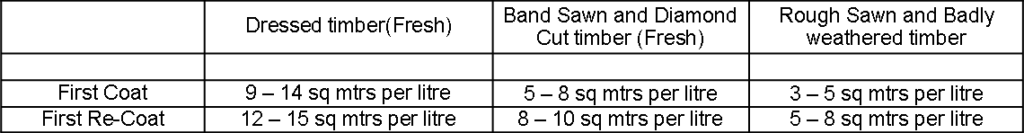

If you’ve waited 5 or 6 years, a standard house wash and recoat often won’t cut it. Restoration at this stage requires a deep chemical clean to strip back dead fibres and mould, followed by multiple applications of oil to quench the thirsty timber.

The hard truth is that while re-oiling helps return flexibility to the wood and releases surface tension, it cannot un-warp a board completely.

Once a board has significantly cupped, the damage is largely irreparable. You can halt the process and protect the wood from further degradation, but you cannot return the board to its original, flat state.

Factors That Speed Up the Clock

The “three-summer rule” is a guide, but your specific environment might move the needle:

- Foliage: Trees or bushes touching the Cedar trap moisture and cause mould.

- Dirt & Splashback: Proximity to garden beds or dirt can lead to ground-level rot.

- Micro-climates: Coastal salt spray or high-humidity bush settings can accelerate the breakdown

Regularly washing your house will often remove these contaminants and should be part of your regular maintenance plan.

Regardless, the longer you wait, the more life you are taking out of the boards. Delaying maintenance might save a bit of money this year, but it effectively shortens the total lifespan of your home’s cladding.

On a sunny face, you aren’t just skipping a service, you’re allowing permanent damage to the surface of the Cedar that can’t be undone later.

Final thoughts…

If in doubt, you always ask us to pop around for a free Cedar assessment. Very often it’s only the sun exposed faces that need maintaining, and it doesn’t cost as much as people might think.